PRODUCT DISPLAY  What is Brake?

What is Brake?

Brake (brake staff) can be divided into two categories, industrial brakes and automotive brakes

Industrial brake industry downstream industry mainly for the lifting of transport machinery, metallurgical equipment, mining equipment, construction machinery, wind power and nuclear power equipment, ships and marine heavy equipment and other manufacturing

Brakes are a new type of construction due to the development of modern industrial machinery. The application of clamp disc brakes, magnetic powder brakes and electromagnetic brakes is the most widely used. Specific categories are as follows:

1, friction brake, which can be divided into disc brakes, outside the block brakes, the expansion of the shoe brakes, belt brakes, integrated belt brakes, double-shoe brakes, multi-shoe brakes, simple belt brakes, Single-disc brakes, multi-disc brakes, fixed clamp brakes, floating brakes and so on.

2, non-friction brake, which can be divided into magnetic brake, magnetic eddy current brakes, water swirl brakes and so on.

More. . .

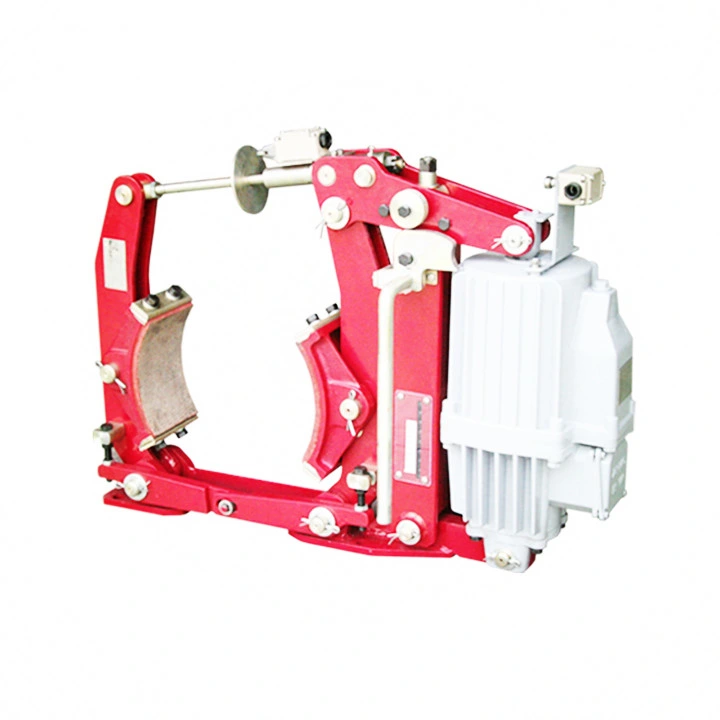

Block brake The brake for a crane consists of a brake pad, a brake arm, a brake wheel and a brake. A brake wheel is often used as a half body of the coupling on the rotating shaft of the mechanism. The symmetrical arrangement of the brake arm is hinged with the frame fixing part. The two brake pads with friction material on the inside are hinged In the two brake arm, under the action of the brake on the brake force, the pair of brake pads in the radial tightening brake wheel to produce braking torque.

Working Principle:

When the power is turned on, the core of the electromagnetic actuator draws the armature against the push rod, and the push rod drives the left brake arm to the left and the main spring is compressed. At the same time, the auxiliary spring to lift the pressure to the right brake arm to the right, two brake arm drive brake block and brake wheel separation, the body can move. When the power cut off, the core loss of magnetic, the attraction of the armature to eliminate, thus lifting the armature on the putter pressure, under the action of the main spring tension, the two brake arms together inward pendulum, driven brake pad hold The brake wheel generates the braking torque; at the same time, the auxiliary spring is compressed. The braking torque is determined by the main spring force, and the auxiliary spring ensures loose clearance. The brake performance of the block brake is largely determined by the performance of the brake.

WHY CHOOSE US

1. More than 10 years crane manufacture experience.

2. Unique International standard indoor warehouse for crane manufacture.

3. We have the senior crane design engineers, with professional design. And very expert crane mechanical and electrical installation engineer team.

4. Our crane sales team will help to supervise the crane whole production and seaport loading, we prefer to confirm every small details.

5. We know how to shipment the crane in a very compact and reasonable way, save sea freight for our oversea crane client.

Packaging Details: | packaging: 1. Electric parts are packed in iron box to reduce distortion in conveying; |

Delivery Day | Within 30 work days after receiving the deposit |

OUR SERVICE

§ Professional mechanical engineers and electrical engineers provide suitable solution only for you!

§ Engineers available to service machinery overseas.

§ We can offer about 12 moths maintenance service.

§ Recieved customer's message about the quality problems,related after sale service managers will help customer solve problems immediately.

COMPANY INFORMATION

Shandong Kaiyuan Heavy Machinery Co., Ltd.,a company specialized in hoisting machinery manufacturing, was established in 2006. It is a member unit of China Heavy Machinery Association. The company has passed ISO9001 International quality system certification and has independent intellectual property rights and industrial property rights, Class A manufacture license of special equipment and Class A special equipment installation and maintenance license.

The company covers an area of 70,000m2, including 30,000m2of plant construction area and 20,000m2 of outdoor area. It has various kinds of hoisting and handling equipment, with steel handling capacity of 10000t. The products are sold to 20 provinces throughout the country and exported to India, Ethiopia, Indonesia, Vietnam and Iran.

In the new period of development, the company will continue adhering to the quality policy of advanced technology, product quality, courteous serviced, customer satisfaction to achieve development innovation, keeping pace with the times and joint development.